Views: 11 Author: Muneeb Siddiqui Publish Time: 2022-11-07 Origin: Site

How Does Laser Cutting Work?

Laser cutting uses a high-power laser which is directed through optics and computer numerical control (CNC) to direct the beam or material. Typically, the process uses a motion control system to follow a CNC or G-code of the pattern that is to be cut onto the material. The focused laser beam burns, melts, vaporises or is blown away by a jet of gas to leave a high-quality surface finished edge.

The laser beam is created by the stimulation of lasing materials through electrical discharges or lamps inside a closed container. The lasing material is amplified by being reflected internally via a partial mirror until its energy is enough for it to escape as a stream of coherent monochromatic light. This light is focused at the work area by mirrors or fibre optics that direct the beam through a lens which intensifies it.

1.A perfect combination of fiber laser with CNC technique

2.Professional CNC control system with user friendly HMI

3.Gantry structure

4.Shuttle loading table

5.AC servo motion control with fully enclosed high precision ball screw and linear slider

6.Auto tracking capacitor sensor to maintain constant focus position

7.High pressure of assisted gas, up to 20Bar

8.Suction system to remove fume and dust

9.Can be extended for pipe cutting

Applications:

Cutting sheet metal , mild steel, stainless steel,titanium, zinc coated steel, etc.

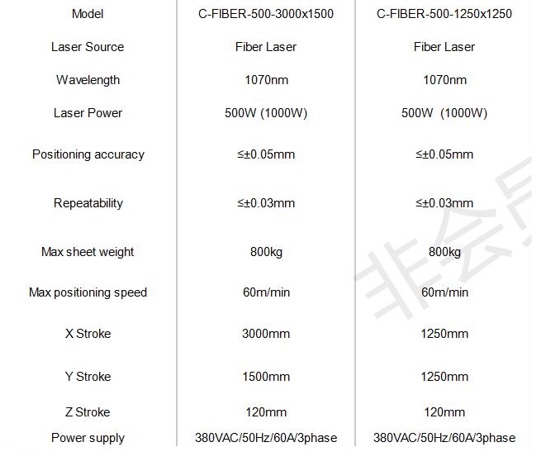

Technical Specifications

Cutting Capabilities